Learning Center

- Why-it-is-so-infectious?

- Preventing black mold from growing.

- What is “Long Covid” loss

- UV tests. How good are they for bacteria detection?

- Latest Titles for Steam Cleaning, September 2020

- Shape-Changing Virus

- Unending – The Salmonella Outbreak!

- What is in a biocide. Are they toxic? Is a disinfectant a biocide?

- Disinfecting aircraft requires proper knowledge of the substances and techniques

- How does one measure the hygienic quality or cleanliness of a surface or object. What does clean mean?

- Hazards of Bleach and Simple Cleaners. Did you know bacteria can survive and hitch rides in space? Did you know bacteria are becoming resistant to antibiotics?

- Why is it important to clean the environment and surfaces? What is the speediest method?

- Levels of Cleaning in Normal Establishments. Reduce microbes, mites, fleas, and bed-bugs with good steam. (Rental Cars, Motels, and Restaurants).

- The History of Hygiene and Sanitation

- Can High-Temperature Steam Inactivate Corona Virus Sars-Cov-2

- Can biofilms be eliminated with steam also a bit of antimicrobial trivia.

- Can one catch Covid -19 in public transport or restaurants

- What is the Difference between a Pandemic and an Epidemic? What is a pathogen?

- Beware of improper cleaning

- What causes bad odors on surfaces? Remove odor with steam – a quick method

- Be careful about the overuse of cleaning chemicals

- Germiest Places and a Lot of Resources

- Constant and Rapid Cleaning is Required in Stores.

- A Graphic Visualization Tool to Understand the Virus Spread

- How does the Coronavirus cause disease spread?

- Deep-cleaning in Hotels and Restaurants is going to be the New Norm

- Bacteria can be ancient

- Don’t spray disinfectants

- As business trickles back, hotels compete on cleanliness Enhanced cleaning is happening everywhere as customers expect new standards

- Is the Nation prepared for the Next Pandemic.

- Restaurants start-up after deep clean with steam

- Coronavirus Remains Investors’ Top Concern For The Week Ahead. Is steam effective?

- MightySteam at the Ohio Food Industry Expo

- How Clean are Your Surfaces?

What is MightySteam®?

A unique high-temperature superheated steam with a temperature higher than the ordinary inversion temperature. MightySteam is at a high temperature, so it is not fog or mist. Learn about steam disinfection, sanitation, and sterilization. Consumers around the world are showing an increased interest in safeguarding their health and boosting their immunity.

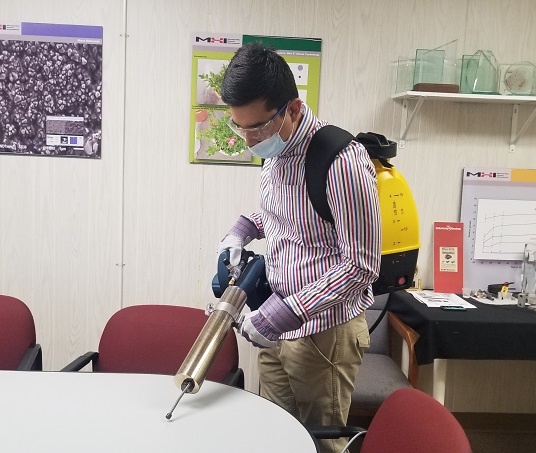

Now SaniZap® machines are available for MightySteam® mobile production and use. USe for Antimicrobial, drying, softening, or humidifying purposes.

The world’s first multi-level cleaner- Chemical Free Antimicrobial- Grease removal – grime removal – dust removal-Superheated Steam Sanitizer

Even PPE (Personal Protective Equipment) like Face Masks can be sanitation level cleaned – when done correctly. The object must be rastered (continuously waved) to not get too hot for the cloth. Viruses and bacteria will be deactivated at temperatures far lower than when the cloth could be damaged. The impact of Sanizap® steam is very rapid. Some fabrics resist heat better than others.

Learning Center

Clean without contaminating means not allowing chemicals to accumulate after cleaning (as they invariably often do in nooks and corners). Today several toddler-use and pet areas are sprayed or cleaned with chemicals. Although without knowing the exact chemical one cannot say if the chemicals are unsafe, it appears that large concentrations of many chemicals may not be fully safe (high concentrations can occur over time if the chemicals are not washed off). With Mightysteam® use we propose a high-quality steam cleaning process.*

SaniZap® machines are portable and mobile steam generators ideal for many unique and routine cleaning requirements. They offer high-temperature super-heated steam jets. Save time and energy with high-temperature enabled speed. Almost four times more temperature than common steam – rapid-on/off for steam as desired. Recent patents, allow the production of the type of steam-cleaning at many levels (from small bacterial- sizes to larger parts). Steam-jet for the loosening of hard-sticky substances. Avoid spreading of harsh/synthetic chemicals- instead, consider high potency clean steam. No worries about any pressure-vessel use. Out of the box use. No worries about accumulating organic residue.

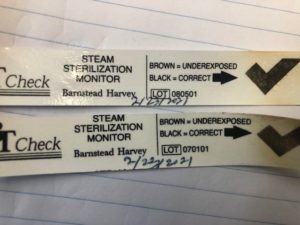

We recommend that you use steam indicators for efficacy and get specific guidance from your local authorities for specific situations.

What is antibacterial and what is antimicrobial: When using chemicals they may not have wide applicability to all species and maybe specific-acting so sometimes we see the word antibacterial being used to denote specific bacteria that have been tested with that chemical. The word antimicrobial is defined as either being valid for a host of microorganisms. Steam has no specificity so is antimicrobial (kills all types of microbes).

Can biofilms be eliminated with steam – a bit of antimicrobial trivia included?

Uses for good quality cleaning steam is contemplated for restaurants, hotels, airports, clean shopping carts, pet-bowls, germy-gyms, and children-use areas. Cleanings for fungus and bed bug-reduction to HVAC coil cleaning and other oil sticky or greasy surfaces. Grease often attracts dust and microbes. Steam sterilization should be used whenever possible on all critical and semi-critical items that are heat and moisture resistant (e.g., steam sterilizable respiratory therapy and anesthesia equipment), even when not essential, to prevent pathogen transmission. Steam sterilizers are used in healthcare facilities to decontaminate microbiological waste and sharps containers.

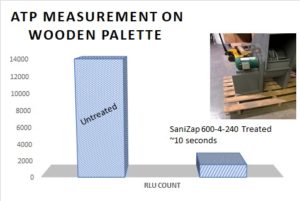

Here is a comparison of Wooden Pallets that were cleaned with the SaniZap-600-4-240 for about 10 seconds.

How long will covid remain on a surface? Could be days depending on the surface – but we don’t know for sure. Some virus remnants could remain and be dangerous even after days. http://www.progressive-charlestown.com/2020/05/we-still-dont-know-how-long-covid-19.html. “The Centers for Disease Control and Prevention says it may be possible for people to contract Covid-19 by touching contaminated surfaces or objects and then touching their mouth, nose, or even eyes,….” (fact sheet)

“Viruses can linger on surfaces, from café counters to water fountains to bathroom sinks, and coronavirus is no exception. For instance, preliminary research published in the New England Journal of Medicine in April, suggests viable coronavirus can stay on plastic and stainless steel for 72 hours, cardboard for 24 hours, and copper for four hours.”

*It should be fully understood that a complete-cleaning regiment may require many types of cleaning methods and every method may have concerns.

Features: Plug and Play, 4 kW power, 208-240 V (50/60 Hz) plug-in, Ground Fault detectors, Temperature Indicator, Access to comprehensive information on anti-bacterial and advanced steam. Supported by an advanced industrial company with many patents and several decades of manufacturing experience in the USA. Advantages: Once plugged in and turned -on, the SaniZap® units begin to generate superheated steam within a minute.

- Highly portable and quiet unit that produces steam very quickly.

- No boiler certifications or intensive training is needed for steam generation.

- Truly plug and play operations and an unmatched 1112°F (600°C) – higher super-heated steam in an easy-to-use compact profile.

- Steam is a penetrative gas and a known agent against microbes. Must be used properly for temperature and residence time.

- Temperature indicators and ground-fault detectors are provided (varies for different machines). Regardless users should, however, familiarize themselves with steam use and safety.

Industrial Strength Superheated Steam

- Dual output conditions allow SaniZap® units to produce high-temperature cleaning steam as well as superheated steam ideal for disinfection.

- SaniZaps’s small profile allows it to be easily stowed away when not in use. Included storage box keeps the SaniZap® unit safe from damage and also doubles as a convenient water reservoir.

- Laboratory tests have shown that within seconds high-temperature steam will denature many bacteria and microbes. Higher temperature steam will need less time to be equally if not more effective. The quality of steam is essential for efficacy and we recommend the use of steam indicators. Steam is a known antimicrobial agent. All disinfecting chemicals or steam are agents. High-temperature steam is a potent non-toxic agent. Periodic treatment with high-temperature steam is recommended (when used correctly) to achieve maximum benefits. Steam quality can sometimes be checked with the proper steam chemical indicators. For bacterial testing, please begin with commonly available test kits (Read this Blog Post for more information on how to determine the cleanliness). When possible, please check with a professional microbiologist.

Safety

Great care must be exercised with the use of steam-producing devices that are used to create and/or direct steam onto any object or surface. MightySteam® from SaniZap® is capable of inflicting steam burns if exposed to skin, so always use the proper personal protective equipment to ensure the operator’s safety. Never operate the machines around small children or animals who may be curious about the steam. Never attempt to “feel” how hot the steam is, you will get burned. Surfaces treated by the MightySteam® may also become warm to the touch, so use caution when touching impacted surfaces.

(source https://en.wikipedia.org/wiki/Brucellosis)

How long will the Covid pathogen remain on a surface? Could be days depending on the surface – but we don’t know for sure. Some virus remnants could remain and be dangerous even after days. http://www.progressive-charlestown.com/2020/05/we-still-dont-know-how-long-covid-19.html. “The Centers for Disease Control and Prevention says it may be possible for people to contract Covid-19 by touching contaminated surfaces or objects and then touching their mouth, nose, or even eyes,….” (fact sheet)

“Viruses can linger on surfaces, from café counters to water fountains to bathroom sinks, and coronavirus is no exception. For instance, preliminary research published in the New England Journal of Medicine in April, suggests viable coronavirus can stay on plastic and stainless steel for 72 hours, cardboard for 24 hours, and copper for four hours.”