Sanizap® Technology

SaniZap® machines offer patented technology and method to clean surfaces faster, more uniformly and often to cleanliness levels than ever before with exciting levels of in Sanitation and disinfection.

- Higher temperatures.

- Faster ramp-up rates.

- Higher efficiencies.

- Higher than common inversion temperatures.

- Better cleaning.

- Self -drying because it is above the inversion temperature

- Clean at many levels. Antimicrobial, dust removal and many more.

- Longer product life.

- No residual organic contamination.

- Extremely rapid degreasing

SaniZap® technology is employed in the MightySteam® line of steam cleaning products and also by the MightySteam® service which represents a service that provides for the cleaning of interior and exterior surfaces utilizing concentrated superheated steam for residential, commercial and industrial purposes.

- Steam Sanitation.

- Food Handling and Processing

- Surface Decontamination

- Remove Odors

- Steam Treatment of Soil

- Bird Dropping Removal (easily dislodge)

- Pest Control

- Several Industrial Applications (grime removal, ceramic drying, food drying)

- Clean Catheters

- Rapid chemical removal and degreasing

MightySteam® is also a service, providing for the cleaning of interior and exterior surfaces utilizing concentrated super-heated steam for residential, commercial and industrial purposes.”

References:

- https://www.cleaning-with-steam.com/food-plant-sanitation-using-steam.html

- Do not contaminate with even commonly used sanitizing chemicals

- BOYD, LESLIE. “Immunology: SIMPLE STEPS CAN REDUCE DUST MITE ALLERGENS IN THE BEDROOM.” RN Oct. 2001: 98. Gale Student Resources In Context. Web. 24 July 2012. [Steam treating carpets and upholstery can reduce allergens]

- https://www.health.com/health/article/0,,20410740,00.html [Germiest places – possible recommended applications for SaniZap]

- https://www.ncbi.nlm.nih.gov/pubmed/22418602 [steam removal of biofilms]

- https://link.springer.com/article/10.1007/s10098-016-1272-2

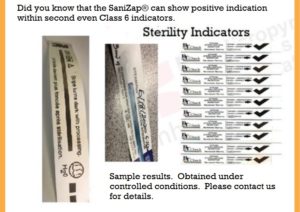

SaniZap® Extender. Limited tests (not yet for public consumption) have shown early efficacy against deactivation of a wide range of micro-organisms including bacteria, viruses, and fungi. These include: Endospore-forming bacteria, including: Geobacillus stearothermophilus: bacillus atrophaeus, vegetative bacteria, Atypical bacteria (i.e. Mycoplasma), Viruses Bacteriophage, Fungi (e.g. Penicillium sp). These results have not been verified independently yet, efforts are underway to create more proof centers with the propagation of the equipment.

- Deep Penetration. Instant Steam. Quickly treat large area surfaces. High velocity. Quick on-off. Defend with MightySteam®.

- High temperature, moisture-free production of non-chemical steam (H2O). No organic residue from this steam. Clean without further contaminating. Novel Technology.

- Use in sensitive spots where chemicals should not accumulate. Sensitive spots include pet-messes and clean rooms. High-velocity steam outlet spray.

- Best energy efficiency with patented steam production. No boiler. On-Off at will. Hi-Q Steam.

- Easily dislodge hard to clean sticky substances with the high temperature steam. Cleanse at many levels.

- Control the temperature easily. With controls and application distance. Improved Productivity. Several programs are provided.

- Recycling of plastics and other non-disposables. A steam cleaning regiment could provide rapid productivity and clean-ability to levels never experienced before – all without chemicals.

- The type of steam cleaning also fits the real ‘clean-up after a clean up’ type of cleaning operation. We recommend rigorous testing with good super-heated steam to ascertain whether new fungus strains of candida may be cleaned.

- All devices feature high-temperature steam above the common inversion temperature.

Why use steam:

- Self drying steam leaves no mess or puddle. Best dusting is with self-drying steam. Vey often ceramics are carefully dried in controlled humidity. So many uses.

- The optimal surface disinfectant for the most demanding hospital environment would have these qualities: Easy to use, quick disinfection, broad kill range, reduce potential of cross-contamination, non-toxic and will not damage surfaces.

- Since the active agent is not a biocidal or toxic chemical (just H2O is the active ingredient) disinfection is exceedingly fast and broad-spectrum. There is no chance of introducing chemical cross-resistance to antibiotics. Surfaces do not become sticky, no stain, or discoloration over time.

- Staff can disinfect as frequently as necessary without long-term chemical exposure concerns.

- The steam cleaning tool is hot, so the potential for cross-contamination from surface to surface or room to room is greatly reduced. This is in sharp-contrast to a fog, spray and wipe approach, which could possibly spread pathogens if the disinfectant is overused or inactivated for any reason including staleness.

- By using proper steam (200°C) any high-touch surfaces can be disinfected on an hourly basis without damage to the surface. Prevents chemical induced irritation to sensitive populations or long-term risks to customers or staff.

- One has to consider steam sanitizing from an objective, scientific perspective: It is a new technology with the potential to reduce pathogen transmission within your facility.

- As steam inactivates microbes very rapidly (seconds with steam compared to minutes for many chemicals), steam is considered a high productivity method.

The SaniZap® steam technology is expected to significantly benefit Sanitation.

The first question people ask is should I use saturated or super-heated steam? The answer is dry super-heated steam of the type available from SaniZap®. Why? Saturated steam could contain water droplets – it is best to avoid this. The slightest amount of cooling of saturated steam could also cause condensation. The rule of thumb is to use dry super-heated pure steam.

What is the difference between Disinfection, Sanitizing, and Sterilization?

Sterilization, is the highest level requiring 99.9999 to 99.999999 or more percent removal of bacteria (contaminants) including spore removal. Also sometimes defines as 6-log to 12- log. This is a technical question so please read the rest of this page and also consult microbiologists for the most technically correct answer. There are 3 fairly commonly accepted levels of “clean” in many industries. Sterilization refers to the statistical destruction and removal of all living organisms to a very high level. Disinfection generally refers to inanimate objects and all vegetative cells, but not spores. Sanitization refers to the reduction of microorganisms to levels considered safe from a public health viewpoint. There appears to be no formal definition of Sanitization, however according to the Association of Official Analytical Chemists, for food product contact surfaces it could be a 99.999% (5-log) reduction of contaminants in a 30 second period of intense treatment. For non-product contact surfaces, a 99.9% (3-log) reduction in contamination could be necessary for Sanitization. It is of course best to try and attain the best levels without further contamination by chemicals or the spreading and accumulation of chemicals that increases their residual concentration.

Drying of Food and Ceramics is similar. Superheated steam has significant advantages.

Drying with superheated steam does have some definite advantages over drying

ceramics or food with hot air. The saturated steam atmosphere transfers the heat more efficiently

to the part than dry, hot air does. Superheated steam has a higher heat capacity and much

higher heat transfer quotient than does dry air making the steam a much better drying

medium. By heating the part completely before evaporation starts, the process allows the

ceramic or food to dry evenly throughout its volume at the same rate. The outer surface does not

dry and shrink first, thereby slowing the drying of the interior. The evaporation rate is

better controlled as is the drying rate, which results in a more uniform ceramic and fewer

cracks due to shrinkage.

References:

- https://pubmed.ncbi.nlm.nih.gov/25162315/

- J. Food Technology, 125(2021) 107942.