Why are the SaniZap® Generators more Efficient than Boiler type of Steam Generators

What type of steam generator should I choose? (Commercial Steam) or (Industrial Steam)

High pressure does not always mean you are getting high-quality steam – in fact, you often get only saturated steam which can easily have moisture (fog and mist). Boilers work on the principle of high temperature by high pressure. Modern steam generators avoid wasting energy that is lost to the high pressure. High-quality steam implies that there is no water droplets (liquid) present in the steam. In the past, the only way to increase steam temperature was to increase the pressure of the boiler. This typically lead to larger boiler size, sometimes unsafe pressures and heavier devices. New patented BoilerFree™ technology allows SaniZap® and MightySteam® units to generate higher temperature steam with in-situ drying air without increasing the size of the device. Steam generators produce steam above the inversion temperature making them ideal for drying, sanitizing, cleaning without leaving behind a mess and many more uses.

The Sanizap® series of steam generators produce steam with high thermal and high kinetic energy. Even among steam generators if the exit steam-gas is not of the right temperature it will condense easily on a surface. The Sanizap® patented technology reduces this tendency. If you are looking for steam generators for the process chemical or pharma sectors then click here.

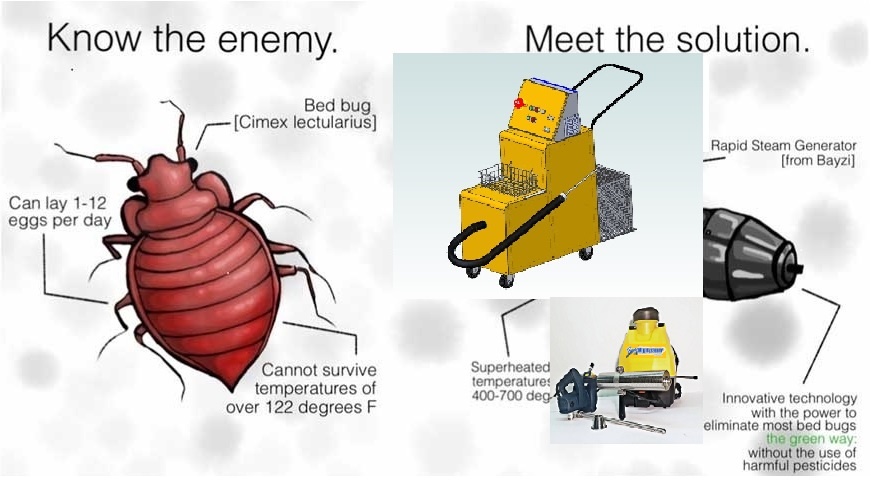

Why is superheated steam far superior to saturated steam? Many bacteria and even viruses thrive in water. Saturated steam can easily contain water droplets which promotes microbe multiplication and even retention. Entropy 2021, 23, 181. https://doi.org/10.3390/e23020181. Superheated steam does not have water droplets. Use steam higher than the inversion temperature like the SaniZap® models produce.

Typical drawbacks of traditional boilers – compared to steam generator cleaners

Broadly speaking Steam Generators (specially 1 atmosphere) yield a higher productivity and better energy efficiency. On the other hand boiler steam commonly suffers from the following problems:

Typically boilers offer limited temperatures. As already mentioned, the only way to increase the steam temperature in the past with the boiler-type of steam was to increase pressure. If you’re in the market for a dry vapor steam cleaner, you have undoubtedly noticed many manufacturers boasting exit temperatures of 121°C (Two Bar, High Pressure Saturated), 134°C (3 Bar, High Pressure Saturated) and even 145°C (4 Bar, High Pressure Saturated) ratings on their units. The SaniZap® offers proper high temperature steam-gas with no water droplets.

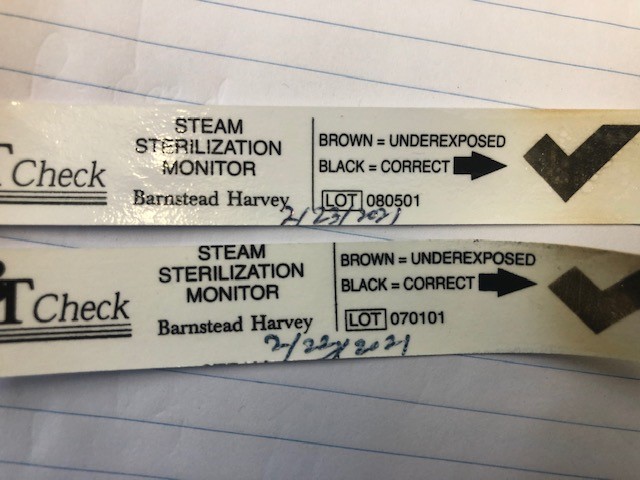

Typically boilers have low temperature steam with high moisture content steam. Even the steam cleaners marketed as “dry vapor steamers” seem to sometimes contain 1-5% liquid-moisture content. While it is dry compared to say, a carpet cleaner, the 1-5% moisture content is still too high to be effective against microbes. This is tested often with a steam indicator. The SaniZap® units are able to turn the appropriate standard steam indicators class 4 and 5 to the correct black color.

Typically boilers have slow startup. Boilers still take anywhere from 10 to 30 minutes to get to the temperature from a cold start, even with preheated water. The SaniZap® units produce steam at the high temperature within 60 seconds of power-on, even for the first start of the day.

Boilers could be highly In-efficient. Other steam cleaners use an in-tank heating element, heating water that isn’t even immediately being used thus causing a constant power usage. Bayzi units are on-off. The MightySteam’s patented SaniZap® technology allow on-the-fly heating. This wastes less energy and makes your cleaning even more green friendly.

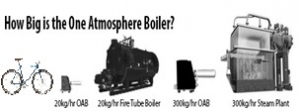

Typically Boilers are Bulky Devices. For higher temperatures, a larger boiler is typically required from boilers. This means more weight and an even more unwieldy carts to be transported (if at all transportable).

Typically Boilers offer low control. With select SaniZap® models, merely turning a knob or activating a switch or using the built in programs can change from high temperature cleaning steam to non-condensing super-heated dry steam, perfect for applications such as disinfecting when deemed and required. Several units have both the manual over-ride feature as well as a fully programmable electronic controls.

For more information and comparisons between steam generators and boilers please click here.

High Temperature super-heated steam carries more enthalpy, or total energy, than air at the same temperature and pressure. For example, air at 1 atm and 300˚C has an enthalpy of 575 kJ/kg. Superheated steam, at the same conditions, has an enthalpy of 3070 kJ/kg. Therefore, superheated steam carries over 5 times the total energy of air at the same conditions. This gives super-heated steam a much larger capacity to do work at the same temperature and pressure.

Low Pressure: Unlike a traditional steam boiler system the steam output for the SaniZap® superheated steam generator is at standard atmospheric pressure. Compare this to boiler systems that must induce large pressures to produce steam at temperatures higher than 100˚C. This provides for a much safer high temperature steam solution and significantly better energy efficiency.