Food Handling/Processing/Cleaning

Hygienic conditions or practices are those that are conducive to maintaining health and preventing disease, especially through cleanliness. More about the history of Hygiene and Sanitation here.

High Contact Area & Bathrooms should be Sanitation level cleaned frequently

Tables and Chairs Sanitized between Groups

Chalk Boards should be frequently cleaned

All food areas should be cleaned and Sanitized very frequently, including rolled silverware

A reliable steam generator is a necessary component of any food manufacturing facility. In addition to generating hot steam for rapid sanitation cleaning purposes, steam is also used to heat pots and ovens, heat the facility during the winter months, and supply steam for batch processing and other food preparation procedures. The SaniZap® allows discrete use as well as multiple nozzles. Steam Generators do not require idling yet make instant steam when required.

The SaniZap® units may be used for a variety of applications in the food industry such as drying of vegetables or for sanitizing vessels, vats and surfaces with the SaniZap-4. Dry rapid steam above the inversion limit.

Clean before start-up

The adjacent pictures show how a restaurant used the steam deep cleaning namely MightySteam® with SaniZap® before starting up after the pandemic related shut down. Traditional cleaning applications typically utilize chemicals, but now this steam technology has become available. Cleaning routines in food process and handling operations feature a basic rinse, clean, rinse, sanitize methodology. Sanitation is more reliable more and versatile to when a steaming routine can be added. Visit HealthySurface® for antimicrobial cleaning and published problems with chemicals. The highly versatile SaniZap® steam units deliver an industrial strength 1112°F (600°C) or higher steam, capable of quickly and effectively cleaning production equipment and environments. Temperature is adjustable. Several cleaning modes are available. Many types of cleaning nozzles are supplied.

For any cleaning method to make an impact the method must address the following bullets that are specific to that sector

- The food processing industry requires quick surface cleaning on all stages of processes and packing

- Corrosive free cleaning is preferable

- The technology must be green and be sustainable. Should not accumulate chemicals.

- Low operating cost

- High food safety from contamination

- Provide safe competitive advantage and reduce risk for all.

- High steam inversion temperature to ensure low treatment time. See water activity information below.

Bayzi Clean Products may help with Odor. No chemicals (except steam!).

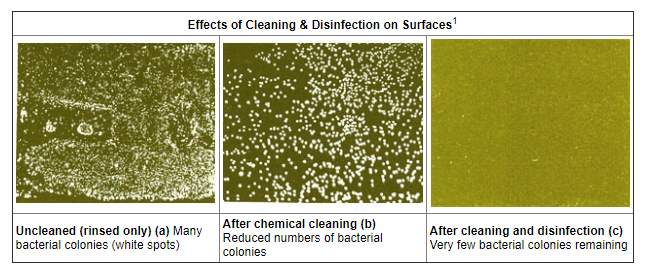

There are 3 commonly accepted levels of “clean” in many industries. Sterilization refers to the statistical destruction and removal of all living organisms. Disinfection refers to inanimate objects and all vegetative cells, but not spores. Sanitation refers to the reduction of microorganisms to levels considered safe from a public health viewpoint. The official definition of sanitization according to the Association of Official Analytical Chemists, for constant food product contact surfaces is a 99.999% (5-log) reduction of contaminants in a 30 second period. For non-product contact surfaces, a 99.9% (3-log) reduction in contamination is necessary.

Machine Impact

Manufacturing Standards specify that most food processing machinery feature a No. 4 ground finish to minimize bacteria growth on the surface.2 Routine exposure to high pressure water or corrosive chemicals may result in pitted, cracked, corroded or roughened surfaces. These conditions can lead to lowered productivity and potential equipment downtime. A high efficiency, low surface impact cleaning solution such as the MightySteam® is capable of effective cleaning without unnecessary wear on surfaces and machinery. Depending on the application, MightySteam® from SaniZap® machines may be able to completely replace certain corrosive chemicals.

Process Impact

SaniZap® machines operate without a high pressure boiler. No high pressure boiler minimizes necessary training and eliminates many certification procedures, allowing for more operators and less downtime. Boiler-less operation also means less waiting for high temperature steam. SaniZap® offers industrial strength superheated steam within one minute of being plugged in. Less waiting, less downtime, higher productivity. The durable method is also highly versatile and easily added to existing cleaning routines. Changing the Settings on The SaniZap® machines after chemical disinfection can remove chemical residues.

Chemical Efficacy

Chemicals can be effective in many applications, but they do have drawbacks. Chemicals can be corrosive, expensive, ineffective after prolong use, time consuming, easy to misuse and potentially dangerous. In many applications, chemical application is a complicated multi-step procedure. As seen below, there is no “cure-all” chemical, rather chemicals well suited for specific applications. MightySteam® is a versatile solution capable of treating a variety of surfaces with varying levels of contamination.

What is Water-activity?

Water activity is equal to equilibrium relative humidity divided by 100: (a w = ERH/100) where ERH is the equilibrium relative humidity (%). Relative humidity sensors of great variety are available for this purpose, including electric hygrometers, dewpoint cells, psychrometers, and others. Because most foods have a high water activity, they can only be sanitized with proper steam with a temperature greater than the inversion temperature. Example with the SaniZap® models.

Is Steam a good Sterilization Method?

High quality steam sterilization is a method that kills microorganisms (includes pathogens) quickly and efficiently. Without steam to transport the high-enthalpy (heat), apparently it takes a lot longer for a dry heat to fully penetrate microorganisms. Steam is the arguably one of the best Sterilization Methods because it’s the fastest, most efficient, cost-effective option available. Steam is just water-gas with no added chemicals to water. Therefore tends to be less problematic for residue – does not spread/accumulate chemicals. Did you know that the new SaniZap® patented technology and machines provide a self-drying™ steam technology?

- Be Careful of disinfectants.

- WHO has begun to alert to the fact that viruses such as the Corona virus may spread on small particles and remain airborne

- Everyone expects a hospital to be clean. However, many traditional cleaning products, floor strippers, and disinfectants present a variety of human health and environmental concerns. They often contribute to poor indoor air quality and may contain chemicals that cause cancer, reproductive disorders, respiratory ailments (including occupational asthma), eye and skin irritation, central nervous system impairment, and other human health effects.

- Don’t spray disinfectants to kill corona-virus, WHO advises

- The most rapid and most dry sanitization with no mess.

Is the resistance to antibiotics is increasing? Why are food processors demanding more cleanability and more energy efficiency?

High temperature superheated steam above the inversion temperature to facilitate drying and bacterial cleaning.

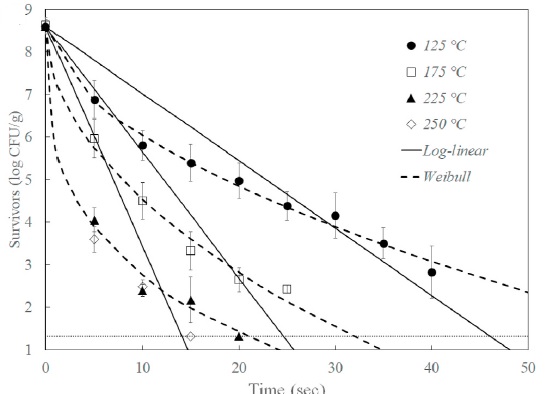

Why use high temperature superheated steam over just hot air for food sanitation and other objects? The water activity (partial pressure of H2O) in a food item containing bacteria item is normally high. Only superheated steam can quickly reduce to even 8-log reduction within seconds Journal of Food Control, vol. 125, 2021. Same as use above the inversion temperature,

Dry Steam above the inversion temperature is the fastest microbial inactivation cleaner.

On-Demand Steam Boilers Improve Food and Brewing Processes. Industrial Steam Heating.

The effect of water activity and temperature ……superheated steam treatment. J. Food Technology, 125(2021) 107942. Joint study by The Ohio State University and Cornell University.

Are you starting-up after a bacteria or virus-related shut-down?

Here are pictures of cleaning including a restaurant doing deep cleaning before starting up again.

Deep-clean the hard-walls well.

Deep-clean floors and boots (with care).

Deep-clean dishes and filters before starting up and every evening. Prevent accumulation of chemical disinfectants where possible

Comparison of the Chemical and Physical Properties in Commonly Used Antimicrobial agents.

| Chlorine | Iodophors | Quarternary ammonium compounds | Acid anionic | Fatty Acid | Peroxyacetic acid | MightySteam® | |

| Irritating to skin | Irritating | Not irritating | Not irritating | Slightly irritating | Slightly irritating | Not irritating | Burns possible |

| Effective at neutral pH | Yes | Depends on type | In most cases | No | No | Yes | Yes |

| Effective at acid pH | Yes, but unstable | Yes | In some cases | Yes, below 3.0-3.5 | Yes, below 3.5-4.0 | Yes | Yes |

| Effective at alkaline pH | Yes, but less than at neutral pH | No | In most cases | No | No | Less effective | Yes |

| Affected by organic material | Yes | Moderately | Moderately | Moderately | Partially | Partially | No |

| Affected by water hardness | No | Slightly | Yes | Slightly | Slightly | Slightly | Requires Water |

| Residual antimicrobial activity | None | Moderate | Yes | Yes | Yes | None | None |

| Cost | Low | High | Moderate | Moderate | Moderate | Moderate | See Now |

| Incompatibilities | Acid solutions, phenols, amines | Highly alkaline detergents | Anionic wetting agents, soaps, and acids | Cationic surfactants and alkaline detergents | Cationic surfactants and alkaline detergents | Reducing agents, metal ions, strong alkalis | N/A |

| Maximum level permitted by FDA without rinse | 200ppm | 25ppm | 200ppm | Varied | Varied | 100-200ppm | N/A |

| Water temperature sensitivity | None | High | Moderate | Moderate | Moderate | None | N/A |

| Foam level | None | Low | Moderate | Low/Moderate | Low | None | N/A |

| Phosphate | None | High | None | High | Moderate | None | N/A |

| Soil load tolerance | None | Low | High | Low | Low | Low | Low |

| *Comparisons made at approved “no-rinse” use levels. Adapted from B.R. Cords and G.R. Dychdala 1993. | |||||||

MightySteam®Cleaning

Studies3 have shown that 250°F (120°C) steam is capable of a 5-log (99.999%) reduction of E. Coli within 2 seconds. The MightySteam® delivers 572°F steam, capable of eliminating a number of surface contaminants quickly and easily.

Resources

1https://www.fao.org/docrep/010/ai407e/AI407E26.htm

2https://edis.ifas.ufl.edu/fs077. Basic Elements for Food Sanitizing

3https://www.imc.cc/other/onsite/hospital-acquired-infections/