Sep 30, 2021 | News

An Ideal sanitizing agent: Steam.

Why?

- approved for food contact surface application.

- has a wide range or scope of activity.

- destroys microorganisms rapidly.

- is stable under all types of conditions.

- is tolerant of a broad range of environmental conditions.

- can dissolve grime and clean.

- H2O has no toxicity and very low corrosivity.

- is inexpensive – just water used in the most optimal way.

- does not leave any chemical residue.

- can penetrate porous objects.

- can work for high or low water activity foods.

- steam is a good agent for even very high microbiological loads

- works against all microorganism even spores.

- works for both gram positive and gram negative microorganisms.

- effective against yeasts, molds, fungi, and viruses.

………………………. more information

More reports:

Sep 21, 2021 | News

Open Source article: BMC Infectious Diseases

BMC Infectious Diseases 2006, 6:130 doi:10.1186/1471-2334-6-130

This article is available from: http://www.biomedcentral.com/1471-2334/6/130

Conclusion: The most common nosocomial pathogens may well survive or persist on surfaces for

months and can thereby be a continuous source of transmission if no regular preventive surface

disinfection is performed.

Main Points: Most gram-positive bacteria, such as Enterococcus spp. (including VRE), Staphylococcus

aureus (including MRSA), or Streptococcus pyogenes, survive for months on dry surfaces. Many gram negative

species, such as Acinetobacter spp., Escherichia coli, Klebsiella spp., Pseudomonas aeruginosa,

Serratia marcescens, or Shigella spp., can also survive for months. A few others, such as Bordetella

pertussis, Haemophilus influenzae, Proteus vulgaris, or Vibrio cholerae, however, persist only for days.

Mycobacteria, including Mycobacterium tuberculosis, and spore-forming bacteria, including Clostridium

difficile, can also survive for months on surfaces. Candida albicans as the most important nosocomial

fungal pathogen can survive up to 4 months on surfaces. Persistence of other yeasts, such as

Torulopsis glabrata, was described to be similar (5 months) or shorter (Candida parapsilosis, 14 days).

Most viruses from the respiratory tract, such as corona, coxsackie, influenza, SARS or rhino virus, can

persist on surfaces for a few days. Viruses from the gastrointestinal tract, such as astrovirus, HAV,

polio- or rota virus, persist for approximately 2 months. Blood-borne viruses, such as HBV or HIV,

can persist for more than one week. Herpes viruses, such as CMV or HSV type 1 and 2, have been

shown to persist from only a few hours up to 7 days.

Sep 3, 2021 | News

An interesting article in NY Times

(may require subscription to open)

Jul 19, 2021 | News

Did you know that bad hygiene can cause even the stock market to fall. Fears about broadly rising coronavirus cases drove the Nasdaq and S&P 500 to their biggest drop in nearly two months, and sent benchmark yields to their largest decline in over 3 months as investors sought shelter from the uncertainty.

https://finance.yahoo.com/news/stock-market-news-live-updates-july-19-2021-221841943-111046902.html

Apr 29, 2021 | News

See article

10 Things to Clean and Disinfect in Your Home

We were alerted by a modern cleaning service to this article. As the pandemic rages (or hopefully wanes), Bayzi and many others have recognized that new new standards for hygenie will be required for providing multilevel cleaning and sanitation. Robust ommunity support for all such efforts is important.

More Information

How to Clean and Disinfect Your Home Against COVID-19 (pennmedicine.org)

Apr 26, 2021 | News

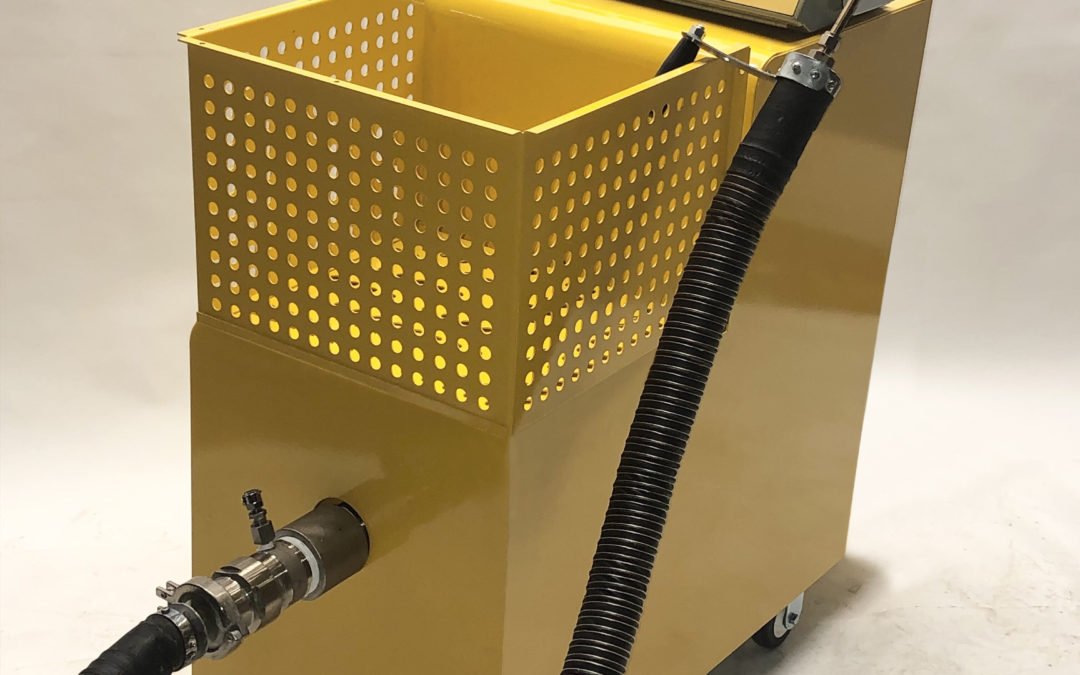

A generous donation helped Bayzi with a SaniZap 1 in a Cincinnati Shelter

shelter cleaning

Shelter cleaning of patient room

Mar 8, 2021 | News

Drying of Food and Ceramics is similar. Superheated steam has significant advantages.

Drying with superheated steam does have some definite advantages over drying

ceramics or food with hot air. The saturated steam atmosphere transfers the heat more efficiently

to the part than dry, hot air does. Superheated steam has a higher heat capacity and much

higher heat transfer quotient than does dry air making the steam a much better drying

medium. By heating the part completely before evaporation starts, the process allows the

ceramic or food to dry evenly throughout its volume at the same rate. The outer surface does not

dry and shrink first, thereby slowing the drying of the interior. The evaporation rate is

better controlled as is the drying rate, which results in a more uniform ceramic and fewer

cracks due to shrinkage.

References:

- https://pubmed.ncbi.nlm.nih.gov/25162315/

- J. Food Technology, 125(2021) 107942.

- https://mhi-inc.com/documents/DryngwithSteambyMCConnelly.pdf