Steam Facts

SaniZap® products with MightySteam®

Super-heated steam does not leave behind any organic residue unless soap or chemicals are deliberately added. Please see below for various steam applications.

Bayzi products are fully patent protected.

Bayzi Steam Fact Pages (Internal and External Studies and Resources):

- Steam Cleaning Efficiency Case Study

- Clean Steam. Dry steam.

- Using Steam for Sanitation Purposes

- Superheated Steam in a Food Processing Environment

- Steam Treating (Noro)virus)

- Household Applications for Steam Cleaning

- Bayzi Case Study – Using Superheated Steam to Treat Soil

- Steam to Remove Bird Poop

- Pest Control Using Steam

- hospital-acquired-infections cleaned with steam

- Basic Elements of Equipment Cleaning and Sanitizing in Food Processing and Handling Operations

- Carcinogen Scorecard – Chemicals Linked to Cancers

- 3 Seconds of Exposure to Superheated Steam Reduces Biofilm Accumulations by 99.95%

- Ranking US Airports by Their Germ Influence

- Study Stating 5 Second Exposure Sterilizes Surface

Some notes on the hardness of water.

Source: https://mhi-inc.com/PG2/steam-superheated-humidity-generator.html

Water Hardness definition.

Grains/Gallon or Parts/Million Description

less than 1.0 less than 17.1 soft

1.0 to 3.5 17.2 to 60 slightly hard

3.6 to 7.0 61 to 120 moderately hard

7.1 to 10.5 121 to 180 hard

10.6 & over 181 & over very hard

More (tallow) soap is required for washing in hard water than in soft water. A water softener

may be required if grains/gallon of water-hardness exceed 3.

Does high-pressure enable the outcome of a steam or chemical reaction for H2O? The short answer is seldom especially above 100°C. Long Answer.

What is more important is having an open-continuous system like the OAB, HGA where molecules of H2O are able to enable more of the desired reaction because of continuous production. This is a steam generator. Provide healthy food options and pay attention to the physical and mental health of employees.

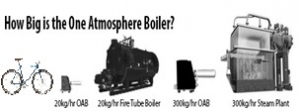

Today, high quality superheated steam is finding many applications in drying, cooking, proper and complete bacterial inactivation, fraking, chemical processes engineering, tablet making, mixing and materials processing. Very high temperature steam at one atmosphere packs the proper punch required for these applications while minimizing the dangers of using high pressure boilers. Given below are the standard steam diagrams for process design. This type of superheated steam is used in applications that have a critical need to reduce the process time. Superheated steam often offers a higher heat transfer coefficient and high enthalpy content that enables many unique uses. When at a high temperature, especially above the inversion temperature, such steam is often considered as a non-toxic antimicrobial agent. Superheated steam at a high temperatures also offers superior reaction for example in energy reactions such as bio-fuels, reforming, hydrogen production, ammonia production, and denaturing, all with rapid heat transfer kinetics.

What is Humidity?

There are several ways to describe the humidity of the air (a term used generally only below 100C, at 1 atmosphere conditions). At high temperatures it is more accurate to talk about Specific Humidity (also called the humidity ratio) which is the mass of water vapor present in a unit mass of dry air; that is, it is the ratio of mass of water vapor to the mass of dry air. Below the saturation temperature (e.g 1 bar, 99.6C) one often uses the term Relative Humidity when steam is mixed with air. Relative humidity is a ratio that compares the amount of water vapor in the air with the amount of water vapor that would be present in the air at saturation. Relative humidity is given as a percentage: the amount of water vapor is expressed as a percent of saturation. Example, at 25oC and 1 atmospheric pressure, the corresponding specific maximum humidity is about 3% although the the relative humidity is at 100%. Endotoxins, microbes and bacteria are known to be inactivated by heat and H2O. All MHI superheated steam productions produces high temperature steam that during production encounters temperatures in excess of 500C. The steam output temperature and condition of humidity are controllable as discussed below for several models.

Vapor pressure measures the water vapor content of the air using the partial pressure of the water vapor in the air. (Pressure may be expressed using a variety of units: pascals, millibars, pounds per square inch (psi), among others). The gases in the atmosphere exert a certain amount of pressure (about 1013 millibars at sea level). Since water vapor is one of the gases in air, it contributes to the total air pressure. The contribution by water vapor is rather small, since water vapor only makes up a few percent of the total mass of a parcel of air. The vapor pressure of the water in the air at sea level, at a temperature of 20oC, is 24 mbar at saturation (about 3% by volume).